Pig Cleaning a Gas Pipeline: How Does It Work?

Pipeline cleaning can be a tricky task if you’re unsure how to tackle it correctly. What’s more, all industrial pipelines demand regular cleaning. That said, gas pipelines probably seem like those with the least issues when it comes to cleanliness and safety. After all, they’re only carrying air, right? Wrong – pig cleaning a gas pipeline is an absolute must-do, too!

Gas pipelines, along with other industrial pipe networks, always demand regular care, cleaning and maintenance to continue delivering product safely. Let’s take a closer look at how pig cleaning a gas pipeline can help to keep your operation running smoothly.

What is pipeline pigging?

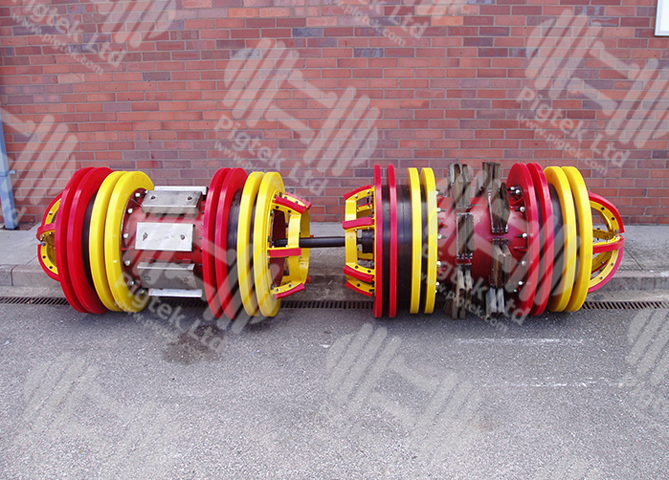

Pipeline pigging involves the use of cylindrical tools known as pigs being sent down industrial pipelines in order to clean, scrub, and/or inspect them for damage and debris.

Pipeline pigs have proven to be essential tools when it comes to industrial pipelines, as they ensure the cleanliness of the inside of the pipeline (and therefore that of the product being sent through), the efficiency of the route (notably when it comes to time that it takes to move a certain amount of product), and the safety of the pipeline itself.

All pipelines are subject to corrosion, cracks, and other damage that not only affect the product being transported, but also pose severe safety risks to anyone in the supply chain. Damaged pipelines are dangerous for your workers, as well as those living nearby – and a damaged pipe potentially expunging gas will likely be doing damage to your local environment.

An inspecting pipeline pig will be able to detect any issues with the interior of a pipe and report it back to you to ensure that any repairs that may need to take place can happen before any bigger issues arise!

Gas pipeline pigs will also carefully scrub and remove ferrous damage and detritus alongside the inside of the pipe’s walls – keeping things moving safely and efficiently.

Why do gas pipelines need pigging?

Although gas pipelines are not quite like their oil or water equivalents, they too need pigging. You might assume that since they transport only gas, they will not face the same issues as other kinds of pipelines – but they’re still at risk of internal corrosion, ferrous debris and blockage.

It’s surprising how much debris can build up over time – even if you are solely transporting gas from one end of a pipeline to the other. Cleaning your pipelines also ensures that your product can remain pure and unspoiled – which is crucial when delivering fuel or raw gas for processing, for example.

How does the gas pipeline pigging procedure work?

Firstly, your specialist pig is designed based on the exact dimensions of your pipeline. At Pigtek, we take painstaking effort to ensure that any pigs set to deploy via your pipe network can navigate even the tightest spots, and the most complex corners and chicanes.

Firstly, your specialist pig is designed based on the exact dimensions of your pipeline. At Pigtek, we take painstaking effort to ensure that any pigs set to deploy via your pipe network can navigate even the tightest spots, and the most complex corners and chicanes.

At the time of pigging, a specialist will provide a pig, a launcher, and pig trap (otherwise known as the receiver). They will deploy your pig into the pipeline, carefully guiding as they do so. It can also simply be moved forward using the flow of the product inside of the pipeline.

The great thing about pigs is that you can continue to send your product through the pipeline being pigged without having to worry about a disruption or halt in the flow!

Once the pipeline pig has carried out its duties by scraping clean the inside of the pipeline, detecting any issues, or even removing another stuck pig, it will then make its way to the receiver, ready to be removed from the pipeline.

Should I pig my gas pipeline?

Yes – gas pipeline cleaning and pigging is crucial. The transportation of gas is dangerous and potentially hazardous at the best of times. But, when it is happening in an unsecured and unclean pipeline, you’re at risk of potentially causing health hazards or even serious damage.

Not only do you risk limiting the transport of your product (with it being slowed down by debris or build-up), but also the potential for a genuine catastrophe if the pipelines corrode or break without you being aware of the issue before it is too late.

If you want to ensure the cleanliness and safety of your gas pipeline, be sure to contact Pigtek. We are a leading designer, manufacturer, and distributor of pigs all over the world – and will work closely with you to ensure your gas pipeline can continue running safely and smoothly for the years to come.

For more information, call us at +44 (0) 1246 850220, or email us at sales@pigtek.com.

Pigtek Ltd

Pigtek Ltd